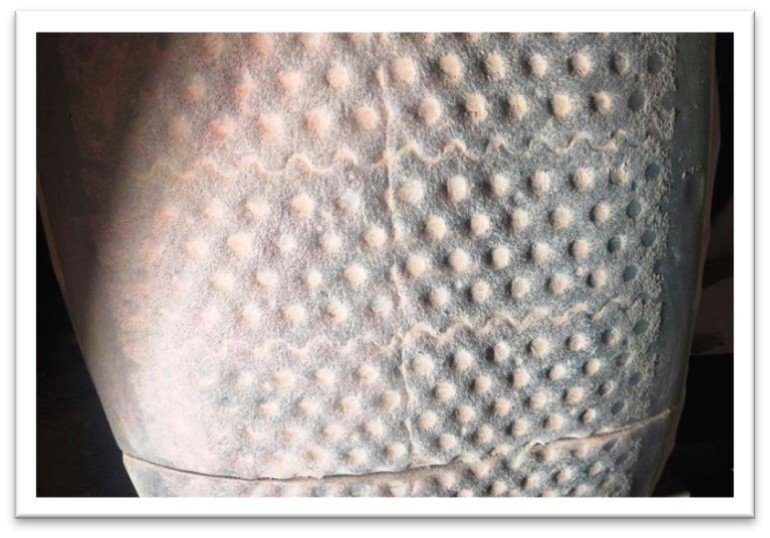

Product – V-Cast Wear Segments for VRM

Location – Middle-East

Client – A Cement plant in the region

Result – 3.5 times improvement in Life of Wear Segments as compared to High Chrome

Vega developed V-cast, a new solution for abrasive grinding conditions. The product is specially designed for providing longer durability based on feed material characteristics of Limestone raw material, Coal, Clinker and Slag.

The customer was facing the following problems in their Raw mill Atox 40 due to highly abrasive feed composition:

• Severe wear on the grinding elements

• Sand blasting effect on mill internal body Liner and Classifier

• Excessive dust load and unstable operation

Vega identified the problem areas by conducting a mill audit and recommended corrective measures in their existing setup along with supply of V-cast roller tires.

Following was the impact observed: –

| Set Details | Conventional Grinding elements | V-cast |

| Running Hours | 5100 | 5100 |

| Wear Depth(mm) | 60.7 | 18 |

| Wear Speed(mm /1000 hrs) | 11.90 | 3.52 |

Post implementation of suggestions the mill operations have observed lower dust load resulting in steady operating conditions. Further, installation of V-cast roller segments resulted in substantial improvement in wear life by three-fold.