AIA Engineering’s greenfield and brownfield manufacturing facilities, with a total capacity of 522,000 MT make us the world’s largest producer of High Chrome Mill Internals. We are also the only company offering end-to-end solutions, from grinding optimization to recovery improvements. All our factories are certified as per ISO 9001:2015 and include world-class production facilities like automated production, heat treatment and robust testing. Further, our Grinding Media facilities in Ahmedabad are also certified as per ISO 14001: 2015 and ISO 45001: 2018.

Maintaining optimal potential

Production Excellence to support your operations

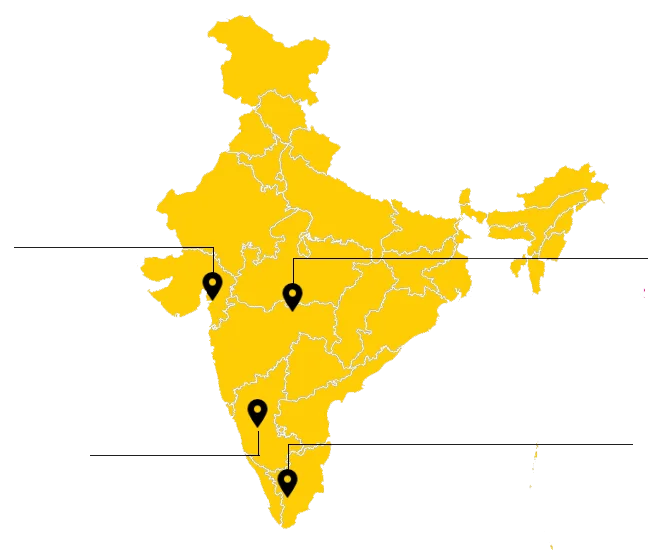

Total Production Capacity

Grinding Media – 340,000 MT

Castings – 110,000 MT

Grinding Media(Expansion) – 80,000 MT

Grinding Media 154,000 MT

116,000 MT

Liners,VRM,Quary 46,000 MT

Centrifugal Casting

4200 MT

Grinding Media

4,000 MT

Grinding Media

28000 MT

AIA Engineering Ltd and Vega Industries believe in strategic global partnerships to further innovations, improve quality and provide holistic services to our client.

EEMS(Energy Efficient Milling Solutions) LLC Has deep expertise in providing energy-efficient solutions to decongest and improve performance of AG/SAG/Ball Mill circuits to the mining industry. This US based partner has expertise in simulations of grinding circuit. They have even designed the innovative and unique EEPL (Energy Efficient Pulp Lifter) liner design through a holistic approach of mill study.

A unique Mine to Metal approach to optimize grind, chemistry and recovery which is done by setting the right grind conditions, identifying the right chemistry and setting the right flotation and /or leach conditions.

Vega Industries partnership with the University of Queensland, Chemical Engineering department has resulted in the UQ-VEGA Grinding And Flotation Chemistry Centre.

This collaboration, lead by Prof Yongjun Pen (Centre Director) at the School of Chemical Engineering, The University of Queensland, brings strong research support team onboard.

Vega Industries has a partnership with Mining Product and Services, Australia.

Mining Products and Service (MPS) is an Australian based company specializes in the Design & Optimization of Mill Linings for the Mineral Processing Industry.

Mining Products and Service (MPS) has over 25 years’ experience in mill lining systems (Liner design, metallurgy, project management, quality control and Optimization). MPS personnel have worked on projects in a diverse range of mineralogical and geographical locations.