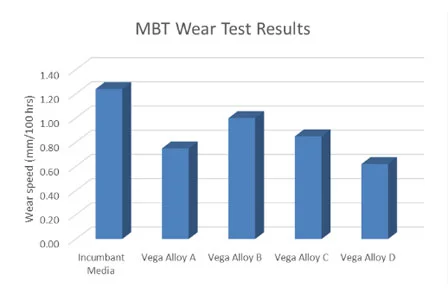

AIA/VEGA manufactures High chromium cast Grinding Media which is wear, corrosion and impact resistant helps in efficient Ball Mill grinding.

Our Grinding Media is tailor made for each milling application. There is a wide range of alloying options which are decided after adequate test work and technical analysis. We manufacture Grinding Media with chrome content ranging from 3% to 33% in sizes ranging from 12mm to 125mm as required by the application.

Enhanced profitability of mining companies is assured with Vega High Chrome Grinding Media solutions.

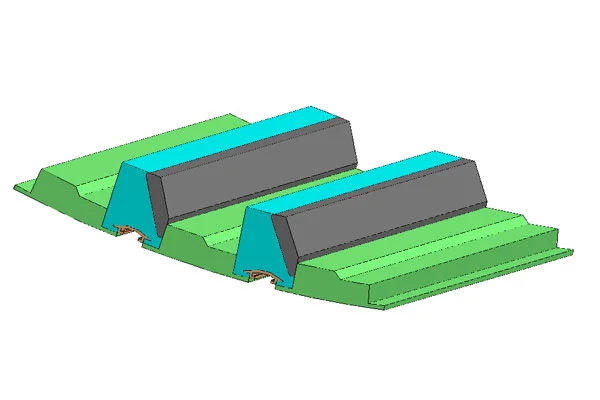

Proprietary liner design and alloys deliver enhanced wear life and throughput in both for AG/SAG mills, Ball mills (Overflow or grate discharge), Vertimill and Rod Mills.

Our Liner design influences milling process in terms of output, grind (particle size distribution) and energy efficiency while improving life without risk of failure. Onsite technical support ensures guaranteed performance.

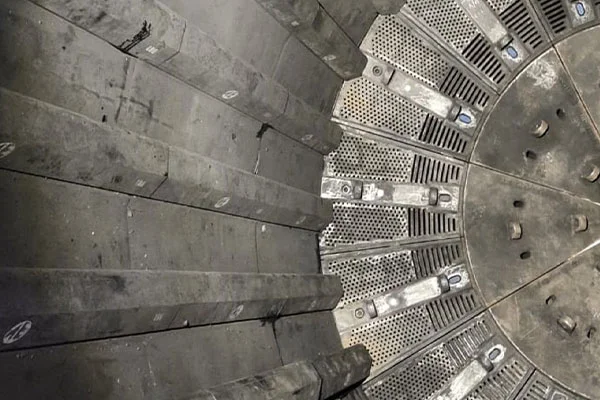

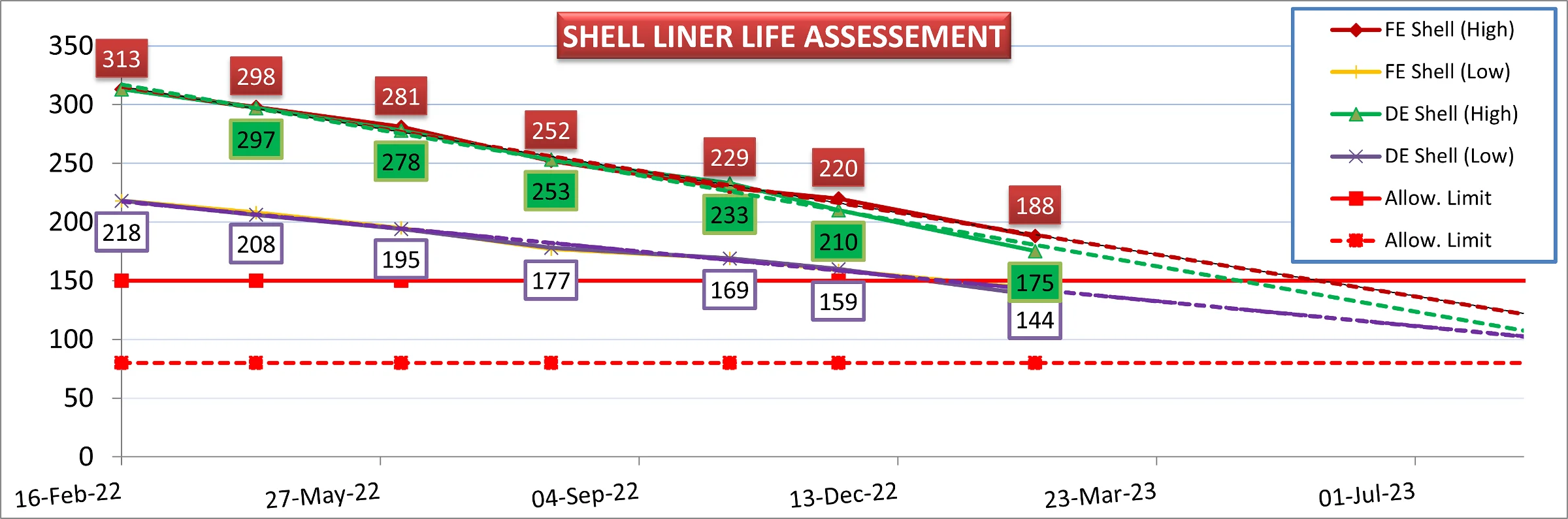

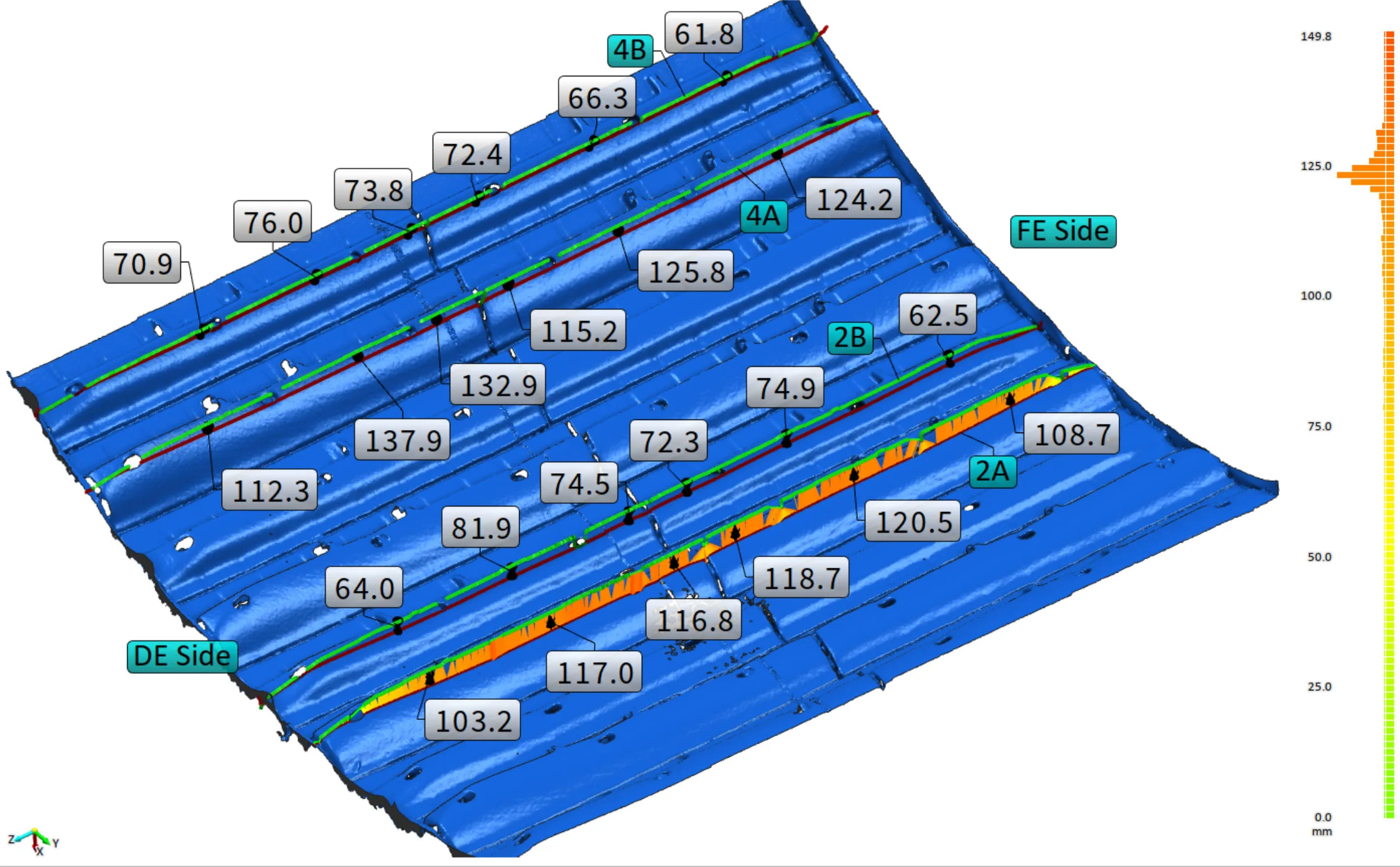

Shell liner design is critical aspect to facilitate efficient mill performance along with higher mill availability.

Vega’s design objectives:

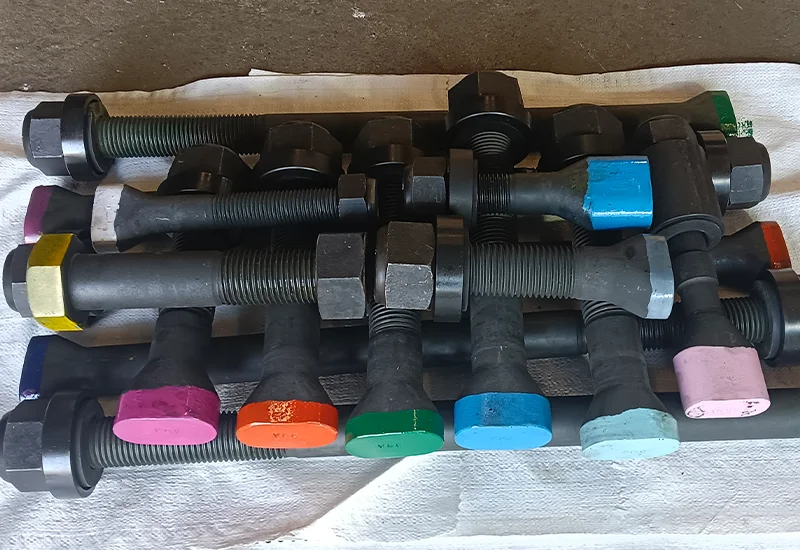

The design is based on multiple parameters such as ore quality, feed size, required product, Grinding Media size and media/pulp volume.

Our design objective is to ensure feed end liners match life of shell liners to reduce multiple mill stoppages.

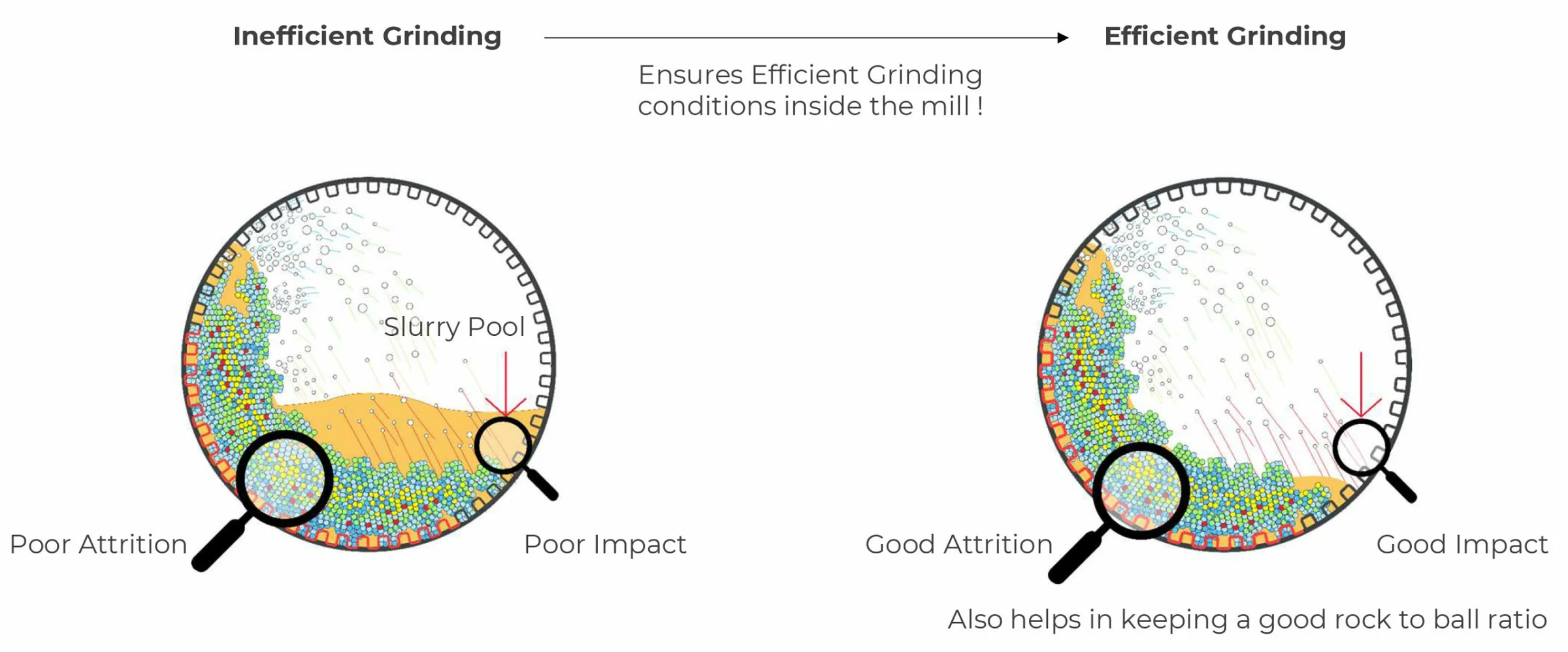

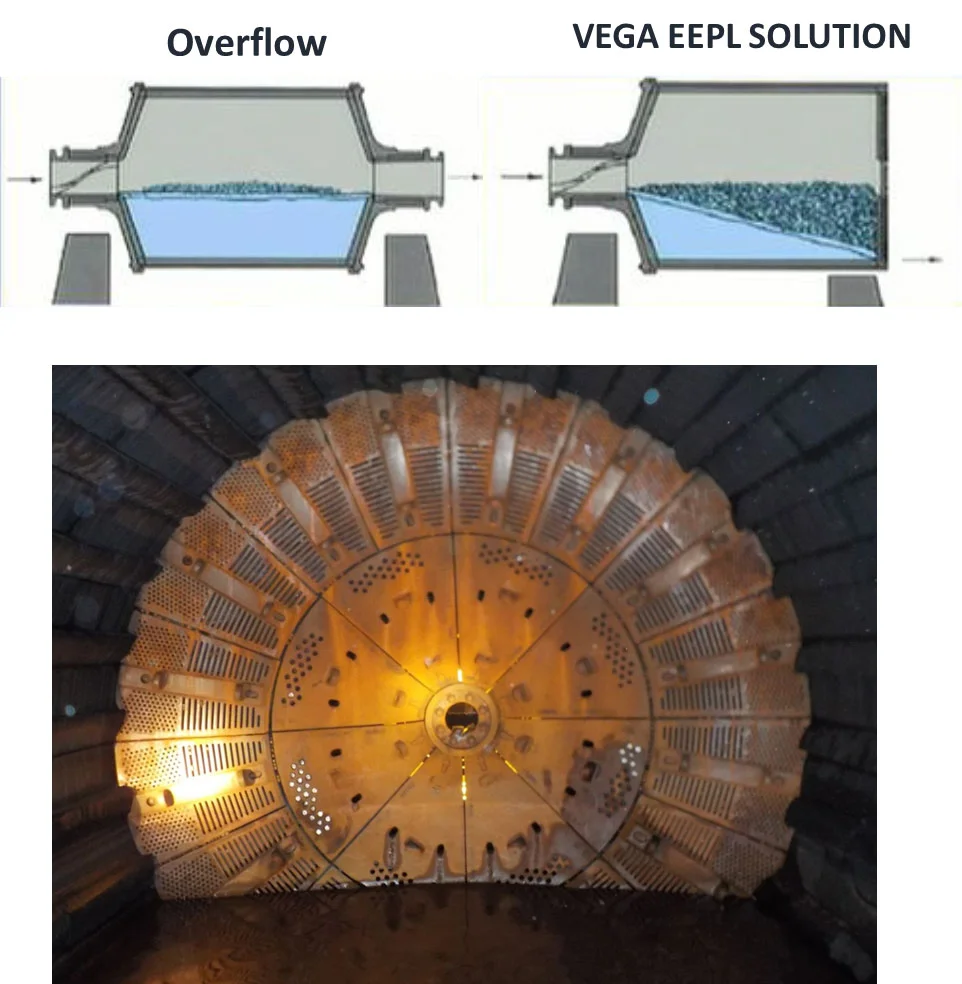

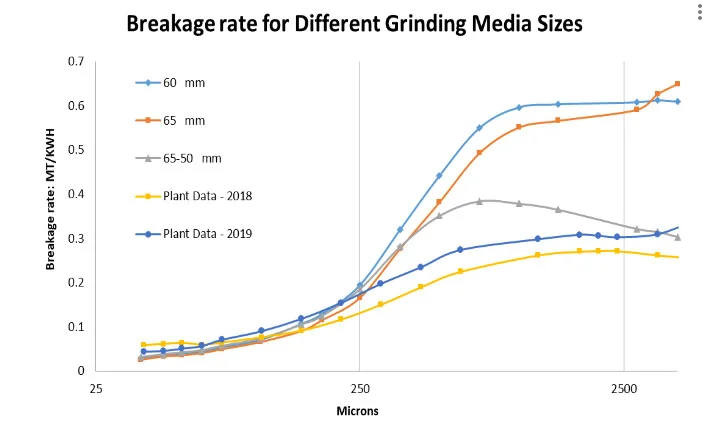

The discharge end liners include pulp lifters and grates (slotted plates) have a pivotal role in SAG mill operation for optimum particle breakage rate, slurry discharge rate, eliminate flow back and slurry pooling. This results into improved performance.

Vega offers its state-of-the-art pulp lifters which are designed using patented EEPL technology for improved grinding efficiency in SAG /AG mills. Our offerings also include conventional radial or curved pulp lifter.

Vega offers optimized Cr-Mo steel and martensitic steel alloys for lining system.

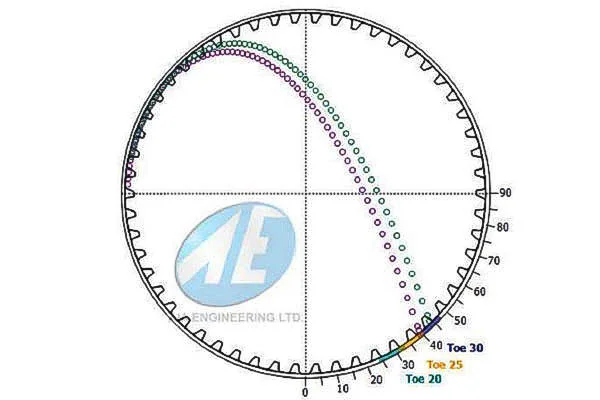

It utilizes an advanced model to predict the motion of the outermost Grinding Media in a rotary grinding mill. MillTraj provides-

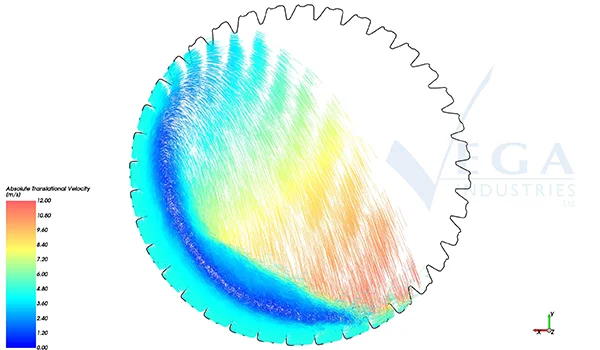

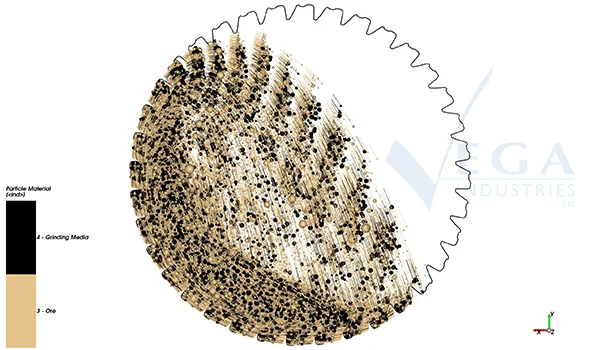

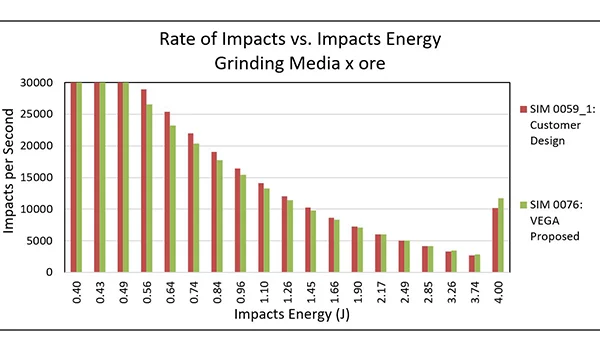

The Discrete Element Method (DEM) is a numerical technique for predicting the behavior of bulk solids. DEM modelling of tumbling mills reveals the characteristics of the mill media motion, predicting the wear of lifters, and energy consumption under various conditions. It helps in simulating several features of SAG mills and AG mills.

Vega offers optimized Cr-Mo steel, martensitic steel and white iron (16 -25% Cr) alloys for Ball Mill Lining System.

Vega offers optimized Cr-Mo steel, martensitic steel and white iron (14 – 26% Cr) alloys for Rod Mill lining system.

These types of mills are common for fine grinding in mining plants. Vega/AIA provides a customised liner solution for better life in mono metal and Sinter cast solutions.

Charge motion and Material transport are pillars for Efficient particle breakage.

SAG Mill: Get highest life and performance than any other pulp lifter design available in Mining Industry.

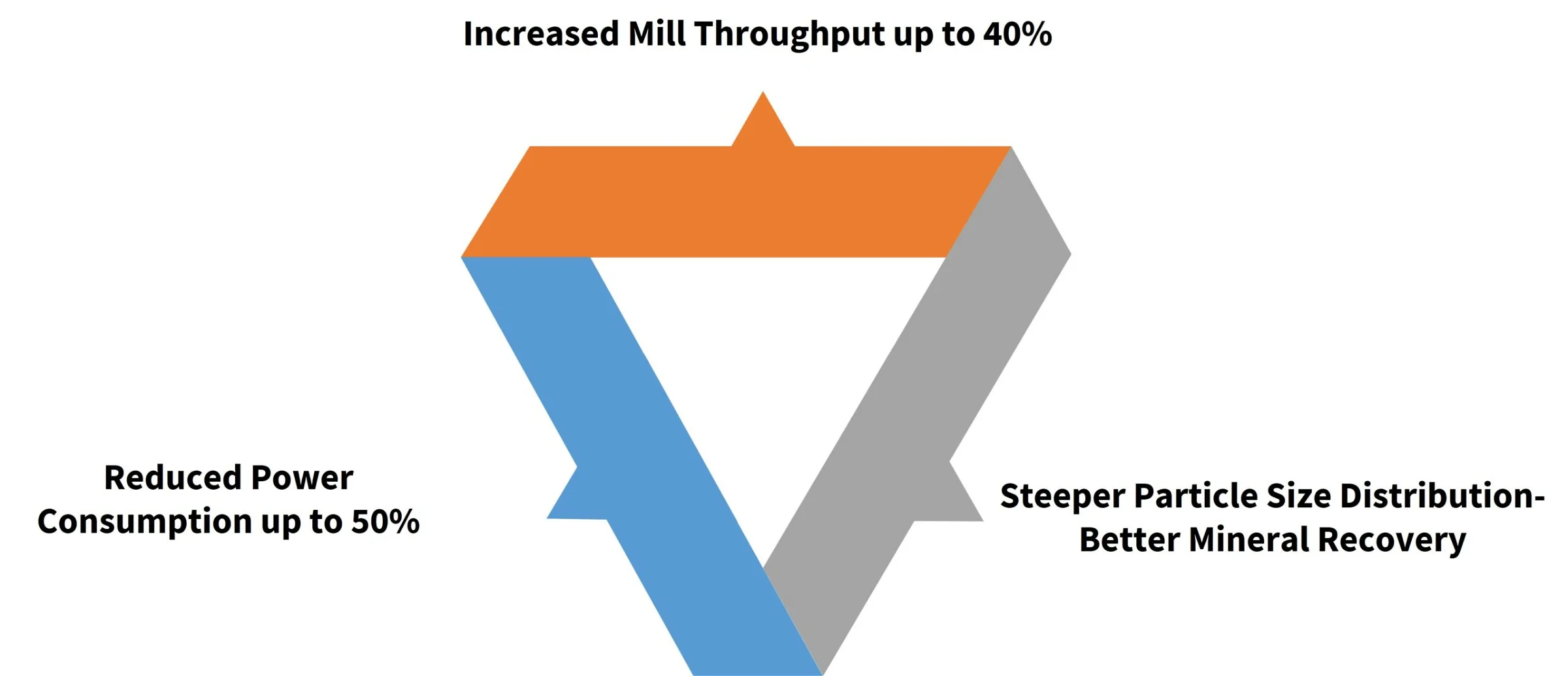

At Vega, our endeavour is to deliver a pioneering solution to the mining industry to tackle modern mining challenges through MillART technique in combination with Ball Mill conversion to EEPL system.

Ball mill conversion project involves installing grates and EEPL system at the discharge end which facilitates flow through grates with a higher hydraulic gradient. Efficiency of Ball Mill operation increases substantially due to improved mineral particle breakage rate and slurry discharge.

Vega’s custom design liner with EEPL as comprehensive solution guarantee the substantial operational profitability.

VEGA is the only company globally that offers MillART which is an innovative and holistic solution resulting into improved liner life, better mill output, energy savings and mineral recovery benefits.

Mill Liner Life

Improvement

Mill Throughput

Improvement

Mill Energy

Reduction

Mineral Recovery

Benefits

AIA Engineering and Vega Industries believe in strategic global partnerships to further innovations, improve quality and provide holistic services to our client.

EEMS ( Energy Efficient Milling Solutions) LLC Has deep expertise in providing energy-efficient solutions to de bottleneck and improve performance of AG/SAG/Ball Mill circuits to the mining industry. This US based partner has expertise in simulations of grinding circuit. They have even designed the innovative and unique EEPL (Energy Efficient Pulp Lifter) liner design through a holistic approach of mill study.

A unique Mine to Metal approach to optimize grind, chemistry and recovery which is done by setting the right grind conditions, identifying the right chemistry and setting the right flotation and /or leach conditions.

Vega Industries partnership with the University of Queensland, Chemical Engineering department has resulted in the UQ-VEGA Grinding And Floatation Chemistry Centre.

This collaboration, lead by Prof Yongjun Pen (Centre Director) at the School of Chemical Engineering, The University of Queensland, brings strong research support team onboard.

Vega Industries has a partnership with Mining Product and Services, Australia.

Mining Products and Service (MPS) is an Australian based company specializes in the Design & Optimization of Mill Linings for the Mineral Processing Industry.

Mining Products and Service (MPS) has over 25 years’ experience in mill lining systems (Liner design, metallurgy, project management, quality control and Optimization). MPS personnel have worked on projects in a diverse range of mineralogical and geographical locations.